FV21 - M series is a miniaturized vector inverter. The product adopts the current international advanced control technology -- V/F vector control technology , which has excellent control performance. High reliability and powerful overload, Full functions, compact size, easy to install, and it is used in different occasions for AC asynchronous motor and synchronous motor to regulate speed. Especially suitable for low power, high economic applications and limited mounting space.

Sample provide:

YESSample freight payer:

BuyerTerm of payment:

T/T, L/C, D/PCustomized:

YESWarranty:

18 MonthsDelivery Time:

5-7 working days for standard series; 7-14 working days for customized AC drivesTransportation:

Express · Sea freight · Land freight · Air freightPackage:

Standard Export Package Carton/WoodAvailability:

OEM/ODM, Minmum Order RequestPlace of Origin:

ChinaShipping Port:

ShandongCertification:

CE, EAC, ISO9001, OHSAS18001, TS16949, SGSProduct Overview

| Item | Description |

| Product Name | Frequency Inverter/ AC Drive |

| Model Number | FV21-M-4TxxGB, FV21-M-2SxxG |

| Power Range | 0.75kW-7.5kW |

| Rated Input Voltage | 3 phase 380V/480V; 1 phase 200V/240V |

| Rated Output Voltage | 3 phase 0 to rated input voltage |

| Input Frequency | 50Hz/60Hz |

| Applicable Motor | Asynchronous Motor, Synchronous Motor |

| Control Mode | V/F Control, V/F Vector Control, Sensorless Vector Control, |

| Communication | Modbus 485 RTU |

| IP Class | Standard IP20 |

| Overload Capacity | 150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature) |

Mini Inverter Feature

■ LCGK Micro Inverter Vector control algorithm and excellent control performance

■ Simple PLC multi-speed function

■ Adaptive for synchronous, asynchronous motor

■ Multiple control modes

■ Simple torque control

■ Applicable to motor with constant torque and variable torque

■ Built-in swing frequency function

■ Rich input and output interfaces

Model Explanation

Product Catalogue

FV21−M−4T□□□GB ; 3 Phase 400V Constant Torque/Heavy-duty Application

|

Power(kW) |

0.75 |

1.5 |

2.2 |

|

|

Motor(kW) |

0.75 |

1.5 |

2.2 |

|

|

Output |

Voltage(V) |

3 ;phase 0~Rated Voltage |

||

|

Rated Current(A) |

2.5 |

3.7 |

5.0 |

|

|

Overload capacity |

150% 1 min,180% 10 second, 200% 0.5 second,interval: 10 minutes (inverse time lag feature) |

|||

|

Input |

Voltage/ frequency |

3 phase 380V~480V;50Hz/60Hz |

||

|

Allowable voltage range |

323V~528V;Voltage imbalance :≤3% ;allowable frequency fluctuation:±5% |

|||

|

Braking unit |

Built-in as standard |

|||

|

IP |

IP20 |

|||

|

Cooling mode |

Forced air cooling |

|||

FV21−M−2S□□□G ; 1 Phase 200V Constant Torque/Heavy-duty Application

|

Power(kW) |

0.75 |

1.5 |

|

|

Motor(kW) |

0.75 |

1.5 |

|

|

Output |

Voltage(V) |

1 phase 0~Rated Voltage |

|

|

Rated Current(A) |

4 |

7.5 |

|

|

Overload capacity |

150% 1 min,180% ;10 second, 200% 0.5 second,interval: 10 minutes (inverse time lag feature) |

||

|

Input |

Voltage/ frequency |

1 phase ;200V~240V;50Hz/60Hz |

|

|

Allowable voltage range |

180V~260V;Voltage imbalance :≤3% ;allowable frequency fluctuation:±5% |

||

|

Braking unit |

Built-in as standard |

||

|

IP |

IP20 |

||

|

Cooling mode |

Forced air cooling |

||

Technical Specifications

|

Control features |

Control mode |

VF control |

Vector VF control |

Non-inductive vector control 1 |

Non-inductive vector control 2 |

|

Starting torque |

1.0Hz ;150% |

1.0Hz ;150% |

0.5Hz ;150% |

0.25Hz ;150% |

|

|

Speed control range |

1:50 |

1:50 |

1:100 |

1:200 |

|

|

Speed accuracy |

± 0.5% |

± 0.5% |

± 0.3% |

± 0.3% |

|

|

Torque control |

N |

N |

Y |

Y |

|

|

Torque control accuracy |

— |

— |

±5% |

±5% |

|

|

Torque response time |

— |

— |

<20ms |

<20ms |

|

|

Product functions |

Key functions |

Under-voltage adjustment, switching running command reference(operation panel, terminal and communication), speed tracing, multi−step frequency, Built-in simple PLC multi-segment speed function,auto tuning, S curve acceleration and deceleration, slip compensation, PID adjustment, Swing frequency function,drooping control, current limiting control, manual or auto torque boost. current limiting, multi−functional input and output terminal, Built-in timer/counter each |

|||

|

Frequency reference mode |

Nine basic given: keyboard potentiometer to set, keyboard set UP/down keys, analog channel AI1 / AI2 setting, high-speed pulse DI setting, the PID function setting, multistage speed setting, Simple PLC to set, terminal set UP/DN, PC communication Settings, and can be mutual combination and switch. |

||||

|

Frequency range |

0.00~650.00Hz |

||||

|

Startup frequency |

0.00~10.00Hz |

||||

|

Acceleration/ deceleration time |

Linear acceleration and deceleration and S curve acceleration and deceleration, four acceleration and deceleration time, range:0.1~6000.0s |

||||

|

Dynamic braking |

Braking start voltage:105.0~140.0%、braking termination voltage:105.0~150.0% |

||||

|

DC braking |

DC braking initial frequency:0.00~50.00Hz;DC braking current:0.0~150.0%; DC braking time:0.0~60.0s;Without waiting time for start DC braking to realize quick braking |

||||

|

Jog control |

Jog frequency range: 0.00 ~ 650.00 Hz, Jog acceleration and deceleration time 0.1 ~ 6000.0 S |

||||

|

Unique functions |

Multifunctional M key |

The unique multifunctional key can be set as follows: 0: reverse, 1: Jog ; corotation, 2: Jog ;reversal, 3: running indication to be switched by given mode

|

|||

|

Parameter protection |

Standard operating panel can implement all parameters that disables modification |

||||

|

RS485 communication ports |

RS485 communication ports support Modbus protocol (RTU). with a maximum distance of 500m. |

||||

|

Independent duct |

The full series adopts independent duct design and supports the installation of heatsink outside the cabinet |

||||

|

Power on and auto−detection |

Realizing the power on and auto−detection of internal and peripheral circuits, Such as communication abnormality, motor grounding, power under-voltage, etc |

||||

|

Torque control |

Torque control is supported in vector mode |

||||

|

Synchro control |

Support for permanent magnet synchronous motor with no speed sensor open loop control |

||||

|

Protection function |

In the operation of the under-voltage protection, over-current protection with constant speed and acceleration and deceleration, overvoltage protection, over-voltage protection with constant speed, acceleration and deceleration, interference protection, frequency converter to overheating protection, overload protection, underload protection, motor overload protection, current to detect abnormal, short circuit protection on output, grounding protection on output, abnormal lack phase on input and output, abnormal memory, abnormal RS485 communication, inner abnormal upward/downward communication, abnormal PID feedback, abnormal open/closed terminal external equipment, timing protection |

||||

|

Efficiency |

Power class ≥93% at rated power |

||||

|

Environment |

Operating site |

The product shall be mounted vertically in the control cabinet with good ventilation. Horizontal or other installation modes are not allowed. The cooling media is the air. The product shall be installed in the environment free from direct sunlight, dust, corrosive gas, combustible gas, oil mist, steam and drip. |

|||

|

Ambient temperature |

−10 ~ +40ºC, derated at 40 ~ 50ºC, the rated output current shall be decreased by 1% for every temperature rise of 1ºC |

||||

|

Humidity |

5 ~ 95%, no condensing |

||||

|

Altitude |

0 ~ 2000m, when derated above 1000m, the rated output current shall be decreased by 1% for every rise of 100m |

||||

|

Vibration |

3.5 m/s 2,2~9Hz; 10 m/s 2,9~200Hz; 15 m/s 2,200~500Hz |

||||

|

Storage temperature |

−40~+70ºC |

||||

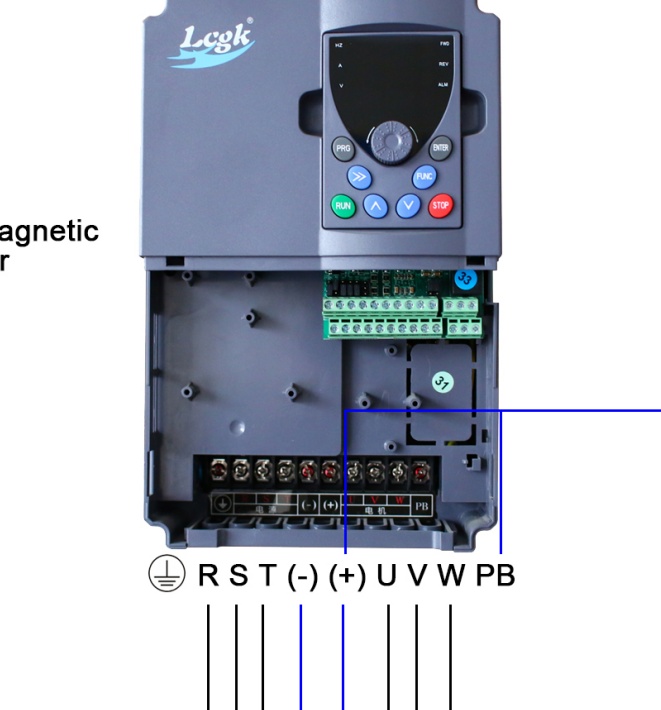

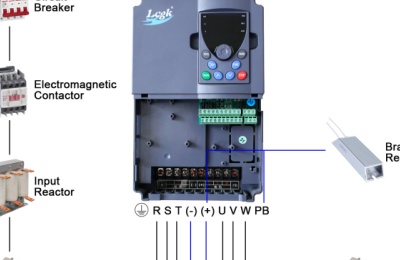

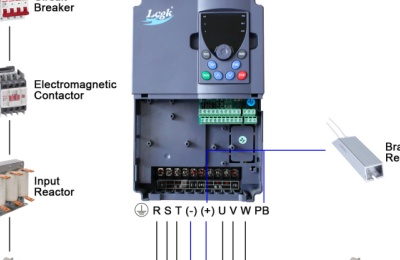

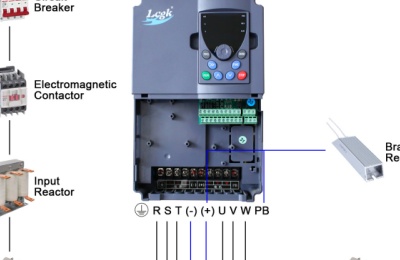

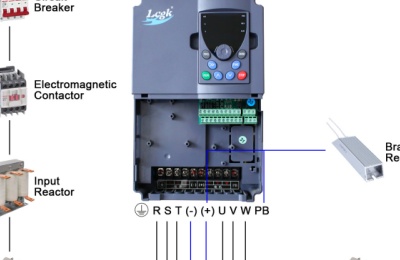

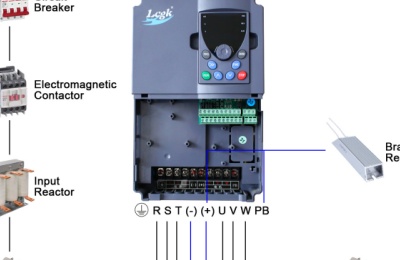

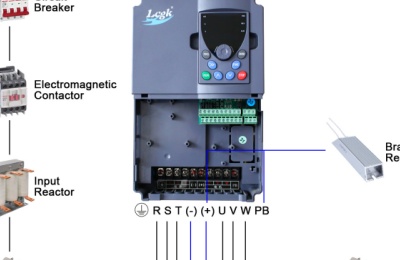

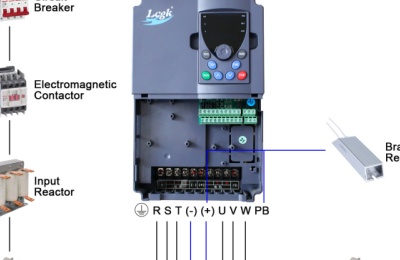

Motor Wiring

Short circuit or grounding of the AC Motor Controller output terminals is prohibited. Otherwise, it will cause damage to the internal components of the drive.

Avoid output cables (U/V/W) short circuit or short circuit to enclosure, otherwise there is a risk of electric shock.

It is strictly forbidden to connect a capacitor or phase lead LC/RC noise filter to the output of the Single Phase To 3 Phase VFD, otherwise the drive will be damaged.

When a contactor is installed between the drive and the motor, the switching action of the output contactor cannot be performed during the operation of the drive, otherwise a large current will flow into the drive to and the drive will report fault information.

Cable length between drive and motor: When the cable between the RS485 Modbus Frequency Drive and the motor is too long, the high-order harmonic leakage current at the output will adversely affect the drive and peripheral devices. It is recommended to install a output AC reactor when the motor cable exceeds 100 meters, and contact the manufacturer to inquire whether the carrier frequency needs to be modified.

Installation Dimension

1 phase and 3 phase mini inverter (mm)

Applications

|

|

|

|

|

|

|

|

|

Representative Industry

Whenever a load has either a variable torque or a variable speed, a VFD should be considered to control torque and speed. Our PLC multi-speed function Inverter are suitable for small Assembly Line, Textile Printing and Dyeing Machinery, Packaging Machinery, Woodworking Machinery and Simple universal fields etc.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

Copyright © 2025 Shandong Lianchuang Gaoke Automation Co.,Ltd.. All Rights Reserved. Power by

IPv6 network supported